Pharma & Food Cap Torque Testing

Bottle Cap Torque Tester

Precision Solutions for Reliable Closure Performance

About Us

Bottle Cap Torque Tester

Bottle cap torque tester ensures caps are tightened to the correct specification, preventing leakage, contamination, or consumer difficulty when opening.

The precise application and removal torque of a bottle cap is a critical factor in product integrity, safety, and user experience. A bottle cap torque tester is the essential instrument that quantifies this force, providing invaluable data for quality control across countless industries. Whether ensuring a child-resistant container functions correctly, maintaining the carbonation in a beverage, or guaranteeing the sterility of a pharmaceutical product, accurate cap torque testing is non-negotiable.

At Cell Instruments, we provide advanced torque testing solutions—including motorized torque tester models like the MCT-01 and precision instruments such as the TT-01—designed for both R&D and production quality control.

Cap Torque Testing is Critical for Quality Control

Why Torque Matters in Cap Torque Testing

The force required to open or close a container is more than just a number; it is a direct indicator of package performance.

The correct application of torque on closures is essential for packaging performance. Too little torque can lead to leaks and compromised safety, while excessive torque can cause breakage, seal damage, or make bottles difficult to open. A closure torque tester provides the accuracy needed to achieve consistent tightening during manufacturing.

Standards such as ASTM D2063, ASTM D3198, and ASTM D3474 outline test methods for measuring application torque, removal torque, and calibration of torque testers. These methods are widely used in the torque tester in pharmaceutical industry, beverages, and food packaging to ensure product reliability and regulatory compliance.

Cap Torque Testing is Critical for Quality Control

Key Applications of Bottle Torque Testing

01

Pharmaceuticals

Ensure compliance with USP and international guidelines by verifying opening torque bottle cap values for child-resistant closures.

02

Food & Beverages

Optimize tightening torque for carbonated drinks, juices, and dairy products to prevent leakage or loss of freshness.

03

Cosmetics & Chemicals

Guarantee safe sealing of detergents, personal care items, and household chemicals.

03

Distribution Simulation

Evaluate torque retention after shipping and handling, as recommended in ASTM D2063 Dynamic Evaluation.

Whether in laboratory testing or production line monitoring, an automatic cap torque tester streamlines torque measurement and ensures repeatable accuracy.

ASTM D2063

- Test Method A (Static Evaluation): Measures removal torque over time after storing bottles in controlled environments (e.g., temperature, humidity). This is critical for assessing long-term seal stability.

- Test Method B (Dynamic Evaluation): Combines torque testing with distribution simulations (per ASTM D4169) to mimic real-world shipping stress. It verifies if caps stay secure during transit.

ASTM D2063 also highlights that sterilization (steam, ethylene oxide, gamma radiation) can alter plastic cap torque—making post-sterilization testing a must for pharmaceuticals.

ASTM D3474

Standard Practice for Calibration and Use of Torque Meters Used in Packaging Applications

ASTM D3474 focuses on the practice for calibrating and using torque meters in packaging applications. It details the calibration process using dead weights to ensure your torque tester for bottles is providing accurate and traceable measurements. Regular calibration as per this standard is not just a best practice—it is a necessity for maintaining data integrity and passing audits, especially in highly regulated fields like the torque tester in pharmaceutical industry.

Cap Torque Testing is Critical for Quality Control

Related Cap Torque Testing Standards

Adherence to internationally recognized standards is the foundation of reliable and reproducible testing. Standards like ASTM D2063, ASTM D3198, and ASTM D3474 provide the rigorous methodologies required for consistent cap torque testing.

MCT-01 & TT-01

Motorized Torque Tester vs. Manual Testing

Selecting the appropriate instrument depends on your application volume, required precision, and compliance needs.

Manual Torque Measurement

As described in ASTM D2063, is suitable for research labs or small-batch testing. However, manual methods can introduce operator variability.

Motorized Torque Tester

Such as Cell Instruments’ MCT-01, eliminates human error by automating cap clamping, rotation, and peak torque recording.

Advantages of motorized torque testing include:

- Consistent and repeatable test results

- Faster throughput for production environments

- Reduced operator influence

- Automatic data recording and software integration

For high-volume industries, automation not only improves accuracy but also reduces labor costs.

Recommended Solutions

Cell Instruments MCT-01 and TT-01 Torque Testers

01

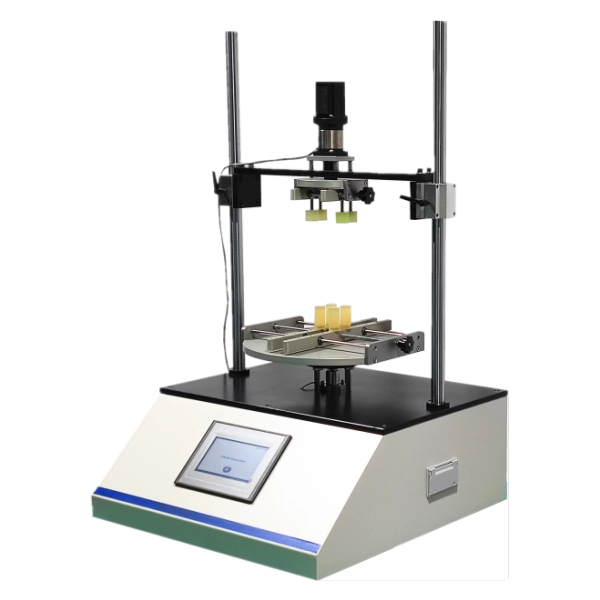

MCT-01 Motorized Cap Torque Tester

The Cell Instruments MCT-01 Motorized Cap Torque Tester is a state-of-the-art system designed for industrial-level stability. Controlled by a PLC and featuring an intuitive HMI touch screen interface, it automates the entire testing process. With its auto clamping and rotating capabilities, it perfectly simulates a production line environment. Key features include automatic peak value retention, dual pneumatic clamping mechanisms, a built-in micro printer, and multiple units of measurement. It is the ideal automatic cap torque tester for high-throughput labs requiring uncompromising data integrity.

02

TT-01 Torque Tester

For applications requiring versatility and precision in a robust package, the Cell Instruments TT-01 Torque Tester is an excellent choice. Also PLC-controlled with a touch screen interface, it offers exceptional accuracy (±1% FS) and a high resolution of 0.001 Nm. Its wide clamp range (Φ5mm~φ170mm) accommodates a vast array of container sizes. Like the MCT-01, it features automatic peak retention, a micro printer, and overload protection, making it a versatile torque tester for bottles of all types.

Bottle Cap Torque Test Demo

Why Choose Cell Instruments for Bottle Cap Torque Testing?

Ensuring Compliance with Torque Testing Standards

Torque measurement is not only a matter of quality—it is also a matter of compliance. International standards guide manufacturers in achieving reliable and repeatable results:

"Methods for torque retention testing using manual devices."

– ASTM D2063

"Procedures for evaluating torque application and removal forces."

– ASTM D3198

"Calibration and correct use of torque meters in packaging."

– ASTM D3474

Experience and expertise

With decades of expertise in torque tester for bottles and other packaging test instruments, Cell Instruments provides:

"Precision-engineered torque testers meeting international standards"

– Cell Instruments

"Solutions for both laboratory R&D and industrial production lines"

– Cell Instruments

"Strong technical support and customized automation services"

– Cell Instruments

"Proven reliability trusted by pharmaceutical, beverage, and quality inspection agencies worldwide"

– Cell Instruments

Frequently Asked Questions about Bottle Cap Torque Testing

1. What is a bottle cap torque tester used for?

It measures the torque needed to apply or remove caps, ensuring packaging is secure but consumer-friendly.

2. Which industries need torque cap testing?

Pharmaceuticals, beverages, cosmetics, chemicals, and food industries all rely on closure torque testing.

3. What standards apply to bottle torque testing?

ASTM D2063, ASTM D3198, and ASTM D3474 are commonly used in packaging torque testing.

4. What is the difference between manual and motorized torque testers?

Manual testers are suited for lab research but may introduce variability, while motorized testers provide automated, consistent, and high-throughput results.

5. Which Cell Instruments models are recommended?

The MCT-01 Motorized Cap Torque Tester for industrial environments and the TT-01 Torque Tester for laboratory applications.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985